Resources

| PDF - Printable Version of Case Study | Download |

Problem Solved!

We've been solving bulk material handling problems for companies around the word for over 80 years. Learn more about some of their experiences below.

| Products Used | Hurricane Air Cannon , Thermo Safety Shield |

|---|---|

| Product Types Used | Air Cannon Solutions , Air Cannons |

| Customer | Secil Outão, Portugal |

The Secil Group, one of Portugal's leading cement producers since 1930, operates three cement plants in Portugal, with an annual production capacity of around 4 million tonnes. The Secil-Outão plant, certified for its commitment to sustainability and adherence to international standards, was exploring ways to revamp its existing preheating tower to optimize material flow and enhance production efficiency. Excessive build-up in the kiln inlet, smoke chamber, calciner, and cyclones was compromising plant performance, leading to reduced productivity, increased downtime, and higher maintenance costs.

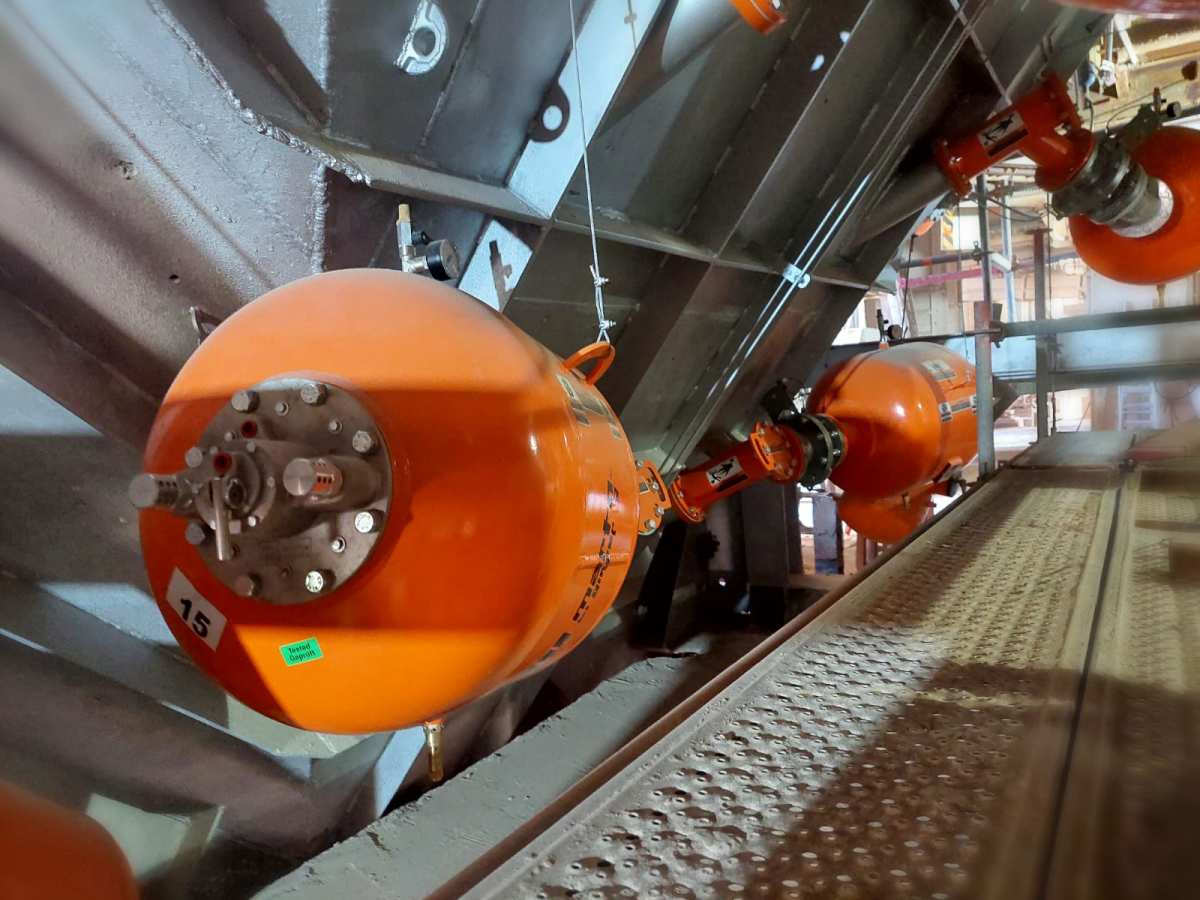

As a result of the ’Walk the Preheater Audit’ conducted by Meteoro, Martin’s distributor in Portugal, a range of solutions were recommended to address the issue, maximize cleaning efficiency, and enhance safety. The suggested solution included Martin® Hurricane Air Cannons, known for their highly effective and compact design. In total, sixty-seven Martin® Hurricane Air Cannons, with varying capacities 35L, 70L, and 150 Ltr, were strategically installed according to the plant's design. These were paired with SMARTª Series High-Temp Nozzles, which can be accessed without removing the air cannons, and Thermo Safety Shields, which act as a safety barrier, enabling timely and safe maintenance of the air cannon systems

Six months after installation, the plant team observed a significant reduction in material build-ups, leading to optimized material flow, reduced downtime, and improved production efficiency. Enhanced safety through the minimization of potential hazards was another key benefit for both the plant and its employees. The company expressed satisfaction with the system's performance and the comprehensive technical support provided throughout the project.

+44(0)115 946 47 46

Martin Engineering Ltd.

Unit 33, The Tangent Business Hub

Weighbridge Road, Shirebrook, NG20 8RX

United Kingdom

Get Directions

info@martin-eng.co.uk

+44(0)115 946 47 46