Eliminate delays, shutdowns and waste so you can boost profitability!

When you’re pushing hard to keep up with the global demand for steel, you can’t allow unexpected shutdowns, equipment failure and runaway waste to slow you down. If you can’t maintain an efficient flow of raw material – including coal, iron ore, coke and limestone – production drops, along with revenues. At the same time, your costs go up due to unscheduled maintenance, inefficient energy use, safety issues and more, which squeezes profits from both sides.

When you’re pushing hard to keep up with the global demand for steel, you can’t allow unexpected shutdowns, equipment failure and runaway waste to slow you down. If you can’t maintain an efficient flow of raw material – including coal, iron ore, coke and limestone – production drops, along with revenues. At the same time, your costs go up due to unscheduled maintenance, inefficient energy use, safety issues and more, which squeezes profits from both sides.

Forty years ago, there were only eight countries capable of producing more than 10 million metric tons of steel per year. In 2014, there were 18 countries that produced that much steel, which means your competition can come from anywhere in the world. All it takes is a mistracked conveyor assembly or an accumulation of fugitive material to force you to shut down operations, especially on older conveyor equipment. Even fugitive dust can cause a plant shutdown for health and safety reasons.

Solving problems with durable, effective solutions.

Solving problems with durable, effective solutions.

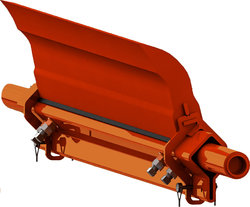

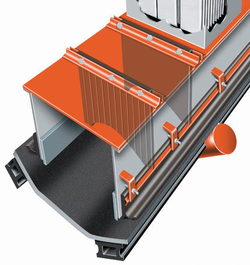

The equipment we manufacture at Martin Engineering is designed to keep materials moving efficiently, quickly and safely throughout your plant. At every key point in the process, starting when the raw material is unloaded from the ship or railcar, our products help you maximize efficiency as material travels through a complex system of conveyors that connect sintering kilns and coke ovens to the blast furnace, basic oxygen furnace or electric arc furnace. We provide durable, effective solutions that clean conveyor belts thoroughly and eliminate carryback. Plus, our transfer point and flow aid products keep material moving through chutes and hoppers and prevent it from sticking to the interior walls of your kilns and silos. And we have the most effective solutions on the market for containing and filtering dust.

Over seven decades, we’ve built a worldwide reputation for solving our customers’ problems in the steel industry. That means whatever your biggest challenge is, we’ve probably seen it before and already come up with a solution that works. So give us a call and let one of our highly experienced engineers apply their expertise to your business.

- Keep downtime for conveyor belt maintenance and belt cleaning to a minimum

- Move material more efficiently along conveyor systems

- Reduce spillage and equipment damage by keeping conveyor belts aligned

- Manage airborne dust and minimize the risk of explosion and inhalation

- Prevent material from spilling off of moving conveyors

- Protect steel workers from extreme temperatures and moving equipment

- Deliver more steel by maximizing overall throughput

- Eliminate excessive downtime for maintenance and housekeeping

- Reduce costs by minimizing waste and reducing energy consumption

MartinPLUS® Maintenance Helps Steel Plant Overcome Regulatory Issues

Air Cannons Eliminate Production Bottlenecks at Steel Production Plant

Martin® Tracker™ Corrects Conveyor Belt Misalignment At Steel Complex

Tracker™ Installation Corrects Spillage and Fugitive Material

Industrial Vibrators And Air Cannons Clear Blockage In Hopper

Air Cannons Move Sticky Coal From Bins

Martin® Impact Cradles Boost Steel Production From 15% to 100%

Conveyor Guards Improve Worker Safety

Air Cannon Installation Results In 80% Fewer Stops For Cleanup

Martin® Belt Cleaner Makes Replacing Worn Blades Easier

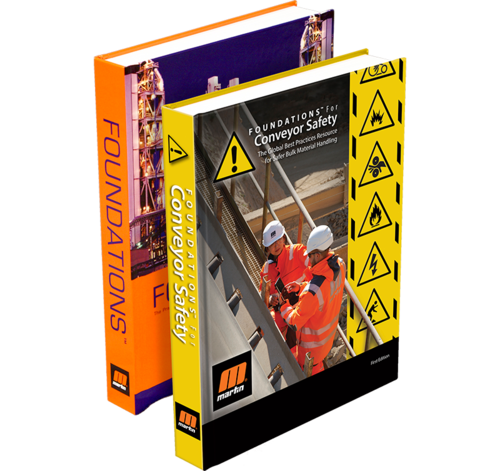

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy

Train Your Personnel For Better Belt Conveyor Performance and Safety

Foundations™ Training workshops train your plant operating and maintenance personnel and engineers about belt conveyors – how they work and how to make them work better. From a Basic Introduction to belt conveyors and safety to an Advanced Training option for your skilled and experienced members, Martin will share our 70 years of experience and research with your team members. You can't afford not to educate your team with Martin!

Ask About Our On-Site and Online Options

Save With Our Martin® Walk the Belt™ Service!

Every conveyor is different, even within the same facility! We can provide regularly-scheduled reviews of your bulk material handling system components, involving a specialized crew with the expertise necessary to achieve high operating standards, keeping the conveyor system running at maximum productivity. Immediate data and photos will be available to facility managers and our suggestions will ensure long-term savings and efficiency.

Get Your Belts Reviewed By People Who Know What They’re Looking At -- At No Charge!