Eliminate your fugitive dust and make your operation safer and more profitable.

When fugitive dust is present in the air, it can hurt your bottom line in several ways. Fugitive dust is a major risk factor for explosions. Coal dust explosions in underground coal mines are prevented by a generous application of rock dust (usually limestone).

When fugitive dust is present in the air, it can hurt your bottom line in several ways. Fugitive dust is a major risk factor for explosions. Coal dust explosions in underground coal mines are prevented by a generous application of rock dust (usually limestone).

Airborne dust poses potential health risks to workers. It can be inhaled and cause chronic illnesses. For example, when coal dust is inhaled, it can build up in the lungs and cause coal worker’s pneumoconiosis, which is more commonly known as “black lung disease.”

Because dust is such a safety and health risk, your insurance costs could go up if it’s not addressed and you run the risk of fines and legal liability, all of which negatively impact the bottom line. Plus, dust can settle on equipment and potentially speed up wear and tear on moving parts, damage electronic equipment and increase housekeeping expenses.

If you would like expert advice on how to best handle your fugitive dust issues, talk to one of our experts. We’re standing ready to listen to you describe your operation and offer recommendations on how to optimize your dust control solutions. Our technicians and engineers are available to provide expert advice and assistance on all of your bulk material handling questions and problems.

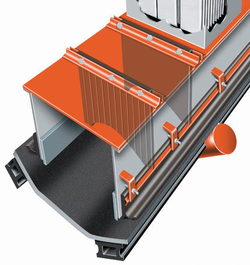

Transfer Point Solutions Result In Safer, More Productive Coal Mining

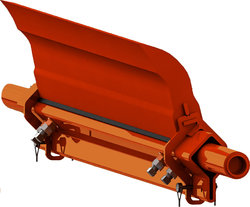

Conveyor Belt Support Products Eliminate Spillage And Increase Productivity

Surfactant Dust System Improves Employee Safety At Copper Mine

Train Your Personnel For Better Belt Conveyor Performance and Safety

Foundations™ Training workshops train your plant operating and maintenance personnel and engineers about belt conveyors – how they work and how to make them work better. From a Basic Introduction to belt conveyors and safety to an Advanced Training option for your skilled and experienced members, Martin will share our 70 years of experience and research with your team members. You can't afford not to educate your team with Martin!

Ask About Our On-Site and Online Options

We've solved your problem somewhere before!

While your problem seems unique and frustrating, with 70+ years of solving similar problems around the world, and with the most experienced and educated people on our teams, we can assure you that we’ve “Been There, Done That.” At least close enough to know what needs to be done next and adjust for your situation.

Put Us To The Test For Free! Let Us Give You a Solution.