We provide solutions that optimize consistency and quality and improve profitability.

When you’re in the business of food processing and manufacturing, you spend a lot of time thinking about quality. More than any other product type, your quality has to be as close to perfect as possible when it leaves the plant because, if the flavor, smell or texture is just a little off, you’ll be hearing from some unhappy consumers! While your ingredients and raw materials are clearly the most important factor in food quality, your process also has a substantial impact.

When you’re in the business of food processing and manufacturing, you spend a lot of time thinking about quality. More than any other product type, your quality has to be as close to perfect as possible when it leaves the plant because, if the flavor, smell or texture is just a little off, you’ll be hearing from some unhappy consumers! While your ingredients and raw materials are clearly the most important factor in food quality, your process also has a substantial impact.

For companies that transport raw ingredients in bulk – such as producers of sugar, grain, barley or corn – complex industrial conveyor systems are usually in heavy use. The primary challenge with conveyor belts is keeping material on the belt. When conveyor belts are not correctly tracked or the transfer points are out of alignment, bulk materials can easily spill off the sides or generate fugitive dust, which can cause an explosion or be inhaled by workers. With material that contains a lot of moisture, such as the bagasse byproduct of sugar production, it can stick to the belt and travel back to the tail pulley, where it can damage equipment. Plus, once it spills off the belt, it can't be recovered, so it results in lost product.

For companies that transport raw ingredients in bulk – such as producers of sugar, grain, barley or corn – complex industrial conveyor systems are usually in heavy use. The primary challenge with conveyor belts is keeping material on the belt. When conveyor belts are not correctly tracked or the transfer points are out of alignment, bulk materials can easily spill off the sides or generate fugitive dust, which can cause an explosion or be inhaled by workers. With material that contains a lot of moisture, such as the bagasse byproduct of sugar production, it can stick to the belt and travel back to the tail pulley, where it can damage equipment. Plus, once it spills off the belt, it can't be recovered, so it results in lost product.

Reliable equipment that’s perfect for food processing and grain handling.

While you’re focusing all this attention on product quality, however, you can’t let productivity drop or profits will suffer. This is where material flow solutions like industrial vibrators and air cannons from Martin Engineering can help. We have decades of experience working with large industrial food manufacturers and have developed a wide range of industrial vibrators that solve a lot of these problems.

At larger facilities where material has to be unloaded from silos or large hoppers, air cannons are an effective way to prevent bridging and obstructions that block the discharge.

At larger facilities where material has to be unloaded from silos or large hoppers, air cannons are an effective way to prevent bridging and obstructions that block the discharge.

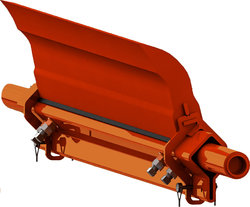

To eliminate the carryback of wet, sticky material on a conveyor system, we manufacture the most durable, effective food-grade belt cleaners on the market, which can be used with a wide range of belt widths, speeds and material types.

So pick up the phone and give us a call. We’ll take the time to listen to you and truly understand your operation and the challenges you’re dealing with, as well as what you’ve already tried as a solution. With our expertise and experience, we’ll be able to recommend a product that gets the job done!

- Keep downtime for maintenance and housekeeping to a minimum

- Move ingredients and products more efficiently through your process

- Eliminate the need to manually break up obstructions in material flow

- Manage airborne dust and minimize the risk of inhalation or explosion

- Deliver more product by maximizing overall throughput

- Eliminate excessive downtime for maintenance and cleanup

- Reduce costs by minimizing waste and reducing energy consumption

Sugar Processor Hires Martin Engineering For Systems Analysis

Secondary Belt Cleaner Eliminates Need For Manual Scraping And Washing

Air Cannons Stop 60,000 Pounds Of Sugar From Sticking To Vessel Walls

Installing Dust Containment Solutions at Sugar Processing Plant

Sonic Horn Eliminates Downtime From Ash Accumulation

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy