Keep your conveyor belts perfectly aligned and running smoothly.

When you’re running a conveyor system in an industrial environment, belt mistracking can be a constant concern. The slightest misalignment can cause major problems, including equipment damage, excessive wear and tear to the belt, and material spillage.

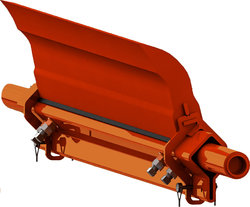

We have decades of experience developing and providing solutions that keep conveyor belts in perfect alignment. Utilizing our the latest designs in transfer point technology, belt cleaning solutions and in some applications, mechanical training devices, we have solutions that ensure your belts run centered and true.

If you’d like to know more about how you can keep your equipment aligned correctly, talk to one of our experts. We’re standing ready to listen to you describe your operation and offer recommendations on how you can boost your bottom line. Our technicians and engineers are available to provide expert advice and assistance on all of your bulk material handling questions and problems.

Tracker™ Installation Corrects Spillage and Fugitive Material

Transfer Point Solutions Correct Conveyor Belt Mistracking

Belt Alignment Products Prevent Excessive Wear And Extend Belt Life

Coal-Fired Power Plant Needed Solution To Conveyor Belt Mistracking

Save With Our Martin® Walk the Belt™ Service!

Every conveyor is different, even within the same facility! We can provide regularly-scheduled reviews of your bulk material handling system components, involving a specialized crew with the expertise necessary to achieve high operating standards, keeping the conveyor system running at maximum productivity. Immediate data and photos will be available to facility managers and our suggestions will ensure long-term savings and efficiency.

Get Your Belts Reviewed By People Who Know What They’re Looking At -- At No Charge!

Our Center for Innovation R&D Facility is one of the Largest and Most Complete in The Bulk Material Handling Industry.

With 22,600 square-feet and numerous employees dedicated every day to furthering improvements and new technologies in our client industries, our Center for Innovation is the place to test your bulk materials in a controlled environment and do full-scale testing of system and component performance.

Bring Your Challenges to the Building Where Earlier Industry-Standard Solutions Were Invented